Series 5 slewing bearing

Axial/radial bearings Series 5:

Series 5 bearing consists of thrust/radial housing washer,a thrust/radial shaft,two

Axial needle roller and cage assemblies and a group of radial cylindrical roller.

Housing washer and shaft washer have equally spaced fitting bolt.This kind

of bearings have high axial load and radial load,and high tilting rigidity and

high precision.This bearing can be used to the machine tool and other high

precision machinery of the rotary table or sub-set,and also can be used for

chuck,measuring instruments and test equipment and rotary table configuration.

This bearing requires higher quality or the parts to match it.You must control

screw tightening torque when install it.

Bearing features:

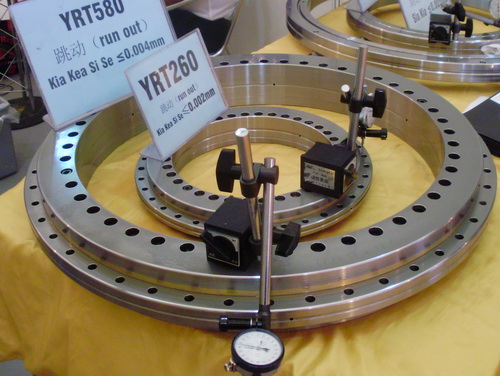

1. High precision: precision at P4, P2.

2. High rigidity: Series 5 bearings are with reload.

3. High load capacity: bearings can support axial load, radial load and tilting load.

4. High speed: Series 5 bearings can be applied in the high speed working condition.

Application scope:

Series 5 bearings are widely used high precision rotary table, vertical grinding machine,

dividing head, hobbing machine, gear generator axis etc.

|

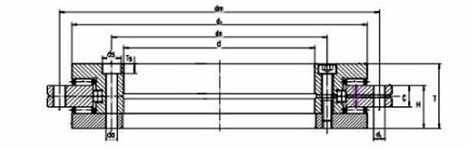

Outside diameter De |

Inside diameter Di |

Mounting height Ht |

H1 |

H2 |

C |

d1 |

dn |

dm |

do |

ds |

Ts |

dL |

Weight Kg |

Designation |

|

126 |

50 |

30 |

20 |

10 |

10 |

105 |

63 |

116 |

5.6 |

9 |

4.2 |

5.6 |

1.6 |

|

|

146 |

80 |

35 |

23.35 |

11.65 |

12 |

130 |

92 |

138 |

5.6 |

10 |

4.2 |

4.6 |

2.4 |

|

|

185 |

100 |

38 |

25 |

13 |

12 |

160 |

112 |

170 |

5.6 |

10 |

5.4 |

5.6 |

4.1 |

|

|

210 |

120 |

40 |

26 |

14 |

12 |

184 |

135 |

195 |

7 |

11 |

6.2 |

7 |

5.3 |

|

|

240 |

150 |

40 |

26 |

14 |

12 |

214 |

165 |

225 |

7 |

11 |

6.2 |

7 |

6.2 |

|

|

280 |

180 |

43 |

29 |

14 |

15 |

244 |

194 |

260 |

7 |

11 |

6.2 |

7 |

7.7 |

|

|

300 |

200 |

45 |

30 |

15 |

15 |

274 |

215 |

285 |

7 |

11 |

6.2 |

7 |

9.7 |

|

|

385 |

260 |

55 |

36.5 |

18.5 |

18 |

345 |

280 |

365 |

9.3 |

15 |

8.2 |

9.3 |

18.3 |

|

|

450 |

325 |

60 |

40 |

20 |

20 |

415 |

342 |

430 |

9.3 |

15 |

8.2 |

9.3 |

25 |

|

|

525 |

395 |

65 |

42.5 |

22.5 |

20 |

486 |

415 |

505 |

9.3 |

15 |

8.2 |

9.3 |

33 |

|

|

600 |

460 |

70 |

46 |

24 |

22 |

560 |

482 |

580 |

10 |

15 |

8.2 |

10 |

45 |

|

|

750 |

580 |

90 |

60 |

30 |

30 |

700 |

610 |

720 |

11.4 |

18 |

11 |

11.4 |

89 |

|

|

870 |

650 |

122 |

78 |

44 |

34 |

800 |

680 |

830 |

14 |

20 |

13 |

14 |

170 |

|

|

1095 |

850 |

124 |

80.5 |

43.5 |

37 |

1018 |

890 |

1055 |

18.5 |

26 |

17 |

18.5 |

253 |

|

|

1200 |

950 |

132 |

86 |

46 |

40 |

1130 |

990 |

1160 |

18.5 |

26 |

17 |

18.5 |

312 |

|

|

1300 |

1030 |

145 |

92.5 |

52.5 |

40 |

1215 |

1075 |

1255 |

18.5 |

26 |

17 |

18.5 |

375 |

|

|

1490 |

1200 |

164 |

108 |

56 |

52 |

1410 |

1240 |

1445 |

18.5 |

26 |

17 |

18.5 |

450 |

|

|

Outside diameter De |

Inside diameter Di |

Mounting height Ht |

H1 |

H2 |

C |

d1 |

dn |

dm |

do |

ds |

Ts |

dL |

Weight Kg |

Designation |

|

mm |

||||||||||||||

|

300 |

200 |

45 |

30 |

15 |

15 |

274 |

215 |

285 |

7 |

11 |

6.2 |

7 |

9.7 |

|

|

385 |

260 |

55 |

36.5 |

18.5 |

18 |

345 |

280 |

365 |

9.3 |

15 |

8.2 |

9.3 |

18.3 |

|

|

450 |

325 |

60 |

40 |

20 |

20 |

415 |

342 |

430 |

9.3 |

15 |

8.2 |

9.3 |

25 |

|

|

525 |

395 |

65 |

42.5 |

22.5 |

20 |

486 |

415 |

505 |

9.3 |

15 |

8.2 |

9.3 |

33 |

|

|

600 |

460 |

70 |

46 |

24 |

22 |

560 |

482 |

580 |

10 |

15 |

8.2 |

10 |

45 |

|