Special bearing steel

To ensure bearings quality, we only buy our bearing steel from a large, reputable and certified steel plant (such as Xingcheng Steel Plant) and all material is meticulously inspected before production. Quality Control ensures compliance with international specifications & standards. The importance of a quality raw material is pivotal in the successful manufacture of a quality bearing. A common cause of fatigue in bearings is the inclusion of non-metallic impurities in the steel.

The bearing's raceways and rolling elements are continuously in contact with one another, for this reason the materials used need to be able to withstand the resultant pressure and friction from an end-user application. They must be able to maintain high precision, rotational accuracy and dimensional stability.

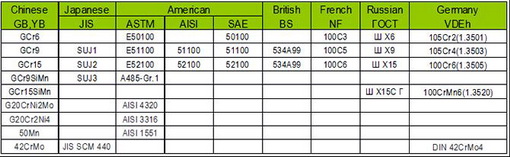

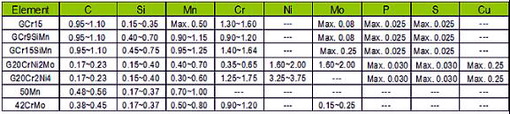

To a large extent the material used for bearing raceways and rolling elements is high carbon chromium bearing steel. For certain applications that require higher impact resistance; one could use a chromium alloy such as molybdenum steel or nickel chromium molybdenum steel. These too should be carburized and quenched appropriately in order to make the hardened layer from the steel surface the appropriate depth.

To a large extent the material used for bearing raceways and rolling elements is high carbon chromium bearing steel. For certain applications that require higher impact resistance; one could use a chromium alloy such as molybdenum steel or nickel chromium molybdenum steel. These too should be carburized and quenched appropriately in order to make the hardened layer from the steel surface the appropriate depth.

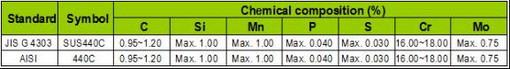

Besides the above mentioned steels, there are certain special applications that require bearings to have higher heat and corrosion resistive properties as well as being capable of enduring extreme speeds. Certain stainless steels could be used for these applications; 440C is probably the most commonly used stainless steel bearing material.

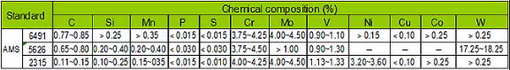

There are other bearing materials available used in Ultra high speed applications and applications requiring a very high level of corrosion resistance. These materials may require one or more of the following characteristics; a low friction coefficient, to be light weight and be able to withstand bearing operational temperatures.

.jpg)